ZDH-2240 Soldador automático TIG | Máquina de soldadura por arco de argón

- Inicio

- ZDH-2240 Soldador automático TIG | Máquina de soldadura por arco de argón

Productos

Solicitar presupuesto

¿Necesita más ayuda?

La empresa siempre se adhiere al espíritu de honestidad y fiabilidad.

+8618678896622

zhangrui018@gmail.com

ZDH-2240 Soldador automático TIG | Máquina de soldadura por arco de argón

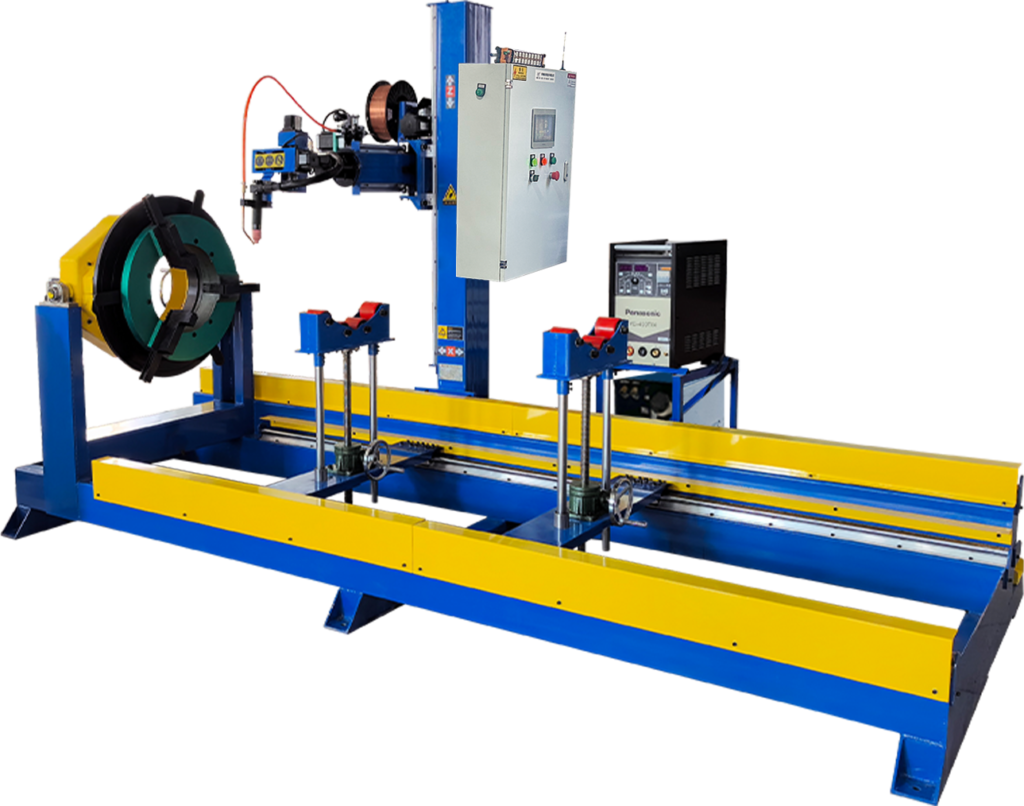

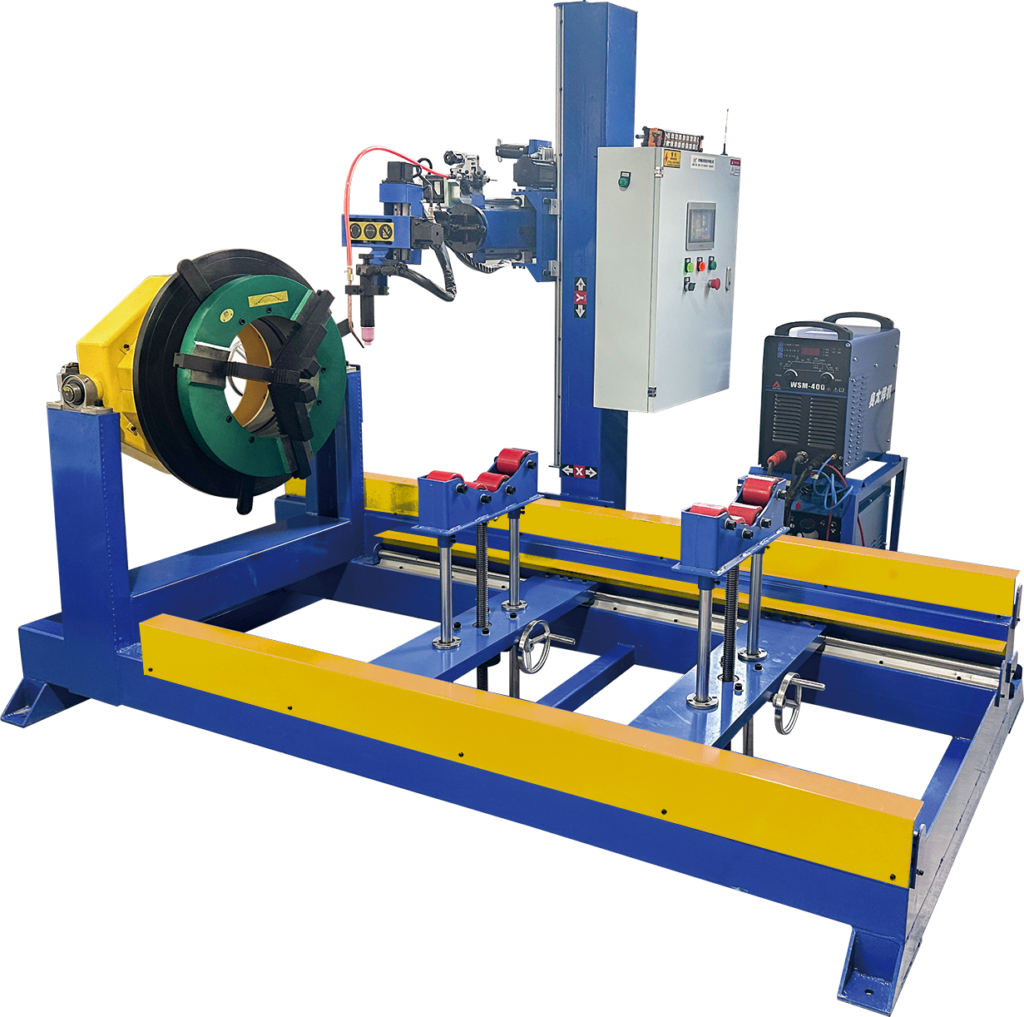

ZDH-2240/2365 equipo automático de soldadura por arco de argón Proceso automático de soldadura brida de acero inoxidable/acero al carbono Soldadura en ángulo

氩弧自动焊2240/2365

Soldadura TIG autoatica

◆Suitable para el tubo, codo del tubo, tee del tubo, tope del reborde del cuello alto del tubo, reborde del tubo, reborde del codo, soldadura recta de la costura del anillo largo del tubo.

◆Adecuado para acero al carbono y acero inoxidable proceso de soldadura de múltiples capas.

◆Puede equiparse con soldadura por arco de argón, soldadura de dos protecciones, MIG, equipos de soldadura MAG.

◆Diseño integrado, estructura compacta, tecnología madura; Posicionamiento preciso de rotación del mandril de tres mordazas autocentrante.

◆3D marco de operación de soldadura + posicionador de ángulo completo + pistola de soldadura Mecanismo de ajuste de ángulo, para asegurar la pistola de soldadura multi-posición, multi-ángulo de conversión.

◆Sistema de control adopta la interfaz hombre-máquina de pantalla táctil grande, fácil programación.

Proceso de soldadura

◆La capacidad de almacenamiento del proceso de soldadura es de 60 conjuntos, y se puede invocar directamente el proceso de soldadura correspondiente según las especificaciones y los números de soldadura.

◆Sistema estándar de seguimiento de la longitud del arco (AVC) y sistema de guiñada de la pistola de soldadura (OSC).

Alimentador de alambre automático ◆CNC, con función de trefilado inverso automático y función de alimentación de alambre pulsante, alta precisión de alimentación de alambre.

El sistema de refrigeración por agua circulante ◆10L garantiza un funcionamiento duradero y fiable de toda la máquina.

◆Una operación del botón, termina automáticamente el proceso entero de la soldadura; La intervención en tiempo real de los parámetros de la soldadura se puede también realizar como sea necesario.

◆Soporte de personalización.

ZDH-2240

ZDH-2365

| Número de modelo | ZDH-2240 | ZDH-2365 |

| Especificación de soldadura | Rango de diámetro de sujeción del mandril 30-650mm¢30-240mm soldadura, puede pasar a través del agujero central, se puede soldar longitud no es más de 2000mm | Rango de diámetro de sujeción del mandril 50-1000mm¢50-360mm soldadura, puede pasar a través del agujero central, se puede soldar longitud no es más de 2000mm |

| Radio de giro | No mayor de 300 mm | No mayor de 500 mm |

| posicionador | Plato de soldadura XH500A, agujero pasante central 240mm, ángulo de cambio 0-90° (manual) | Plato de soldadura XH600A, agujero central 365mm, ángulo de cambio 0-90° (manual) |

| Dimensiones generales | Largo 2500mm ancho 1600mm alto 2100mm(Excluyendo el tamaño de la fuente de poder de soldadura) | Largo 2500mm ancho 1800mm alto 2100mm(Excluyendo el tamaño de la fuente de poder de soldadura) |

| Levantar el soporte | Movimiento axial, ajuste manual de la altura | Movimiento axial, ajuste manual de la altura |

| Fuente de alimentación de soldadura | Estándar equipado con Aotai WSM-400 argón máquina de soldadura por arcoPanasonic YC-400TX4 argón máquina de soldadura por arco es opcional | Estándar equipado con Aotai WSM-400 argón máquina de soldadura por arcoPanasonic YC-400TX4 argón máquina de soldadura por arco es opcional |

| Soplete | Soplete WP27 refrigerado por agua, longitud del cable 5 metros | Soplete WP27 refrigerado por agua, longitud del cable 5 metros |

| Depósito de agua de refrigeración | Circulación interna forzada;Medio refrigerante: anticongelante; Volumen 10L (Shanghai Zhengte) | Circulación interna forzada;Medio refrigerante: anticongelante; Volumen 10L (Shanghai Zhengte) |

| Alimentador de alambre | Adecuado para alambre de soldadura de diámetro 0,8-1,0-1,2-1,6mm,Velocidad de alimentación del alambre 0-5000mm/min. | Adecuado para alambre de soldadura de diámetro 0,8-1,0-1,2-1,6mm,Velocidad de alimentación del alambre 0-5000mm/min. |

| wiggler | Oscilación 0-100mm; Velocidad de oscilación 0-50mm/s,Tiempo de permanencia unilateral 0-10s | Oscilación 0-100mm; Velocidad de oscilación 0-50mm/s,Tiempo de permanencia unilateral 0-10s |

| Seguimiento de la longitud del arco | Rango de seguimiento 0-100 mm Velocidad de seguimiento 0-500 Hz, precisión de seguimiento de la longitud de arco 0,1 V | Rango de seguimiento 0-100 mm Velocidad de seguimiento 0-500 Hz, precisión de seguimiento de la longitud de arco 0,1 V |

| Caja de control | Pantalla táctil PLC, puede almacenar 50 conjuntos de parámetros de proceso de soldadura, control remoto inalámbrico | Pantalla táctil PLC, puede almacenar 50 conjuntos de parámetros de proceso de soldadura, control remoto inalámbrico |

| Número de capas de soldadura | Admite soldadura multicapa y multipaso | Admite soldadura multicapa y multipaso |

| Alimentación | Fuente de potencia de soldadura 20KW/380V/50HZ;Sistema de control 1.0KW/220V/50HZ | Fuente de potencia de soldadura 20KW/380V/50HZ;Sistema de control 1.0KW/220V/50HZ |

产品细节

Detalles del producto

Caja de control PLC

La capacidad de almacenamiento del proceso de soldadura es de 60 juegos

Disponible según especificaciones de soldadura

Invocar directamente el proceso de soldadura correspondiente según el número

Posicionador de orificios pasantes

Puede sujetar piezas de diferentes diámetros

Sujeción estable y precisa

Escobilla de carbón conductora de alto contenido en cobre

Alambre de masa para máquinas de soldar, cuatro alambres de alto cobre

Soldadura continua con corriente de 300 A

Mango de turbina de desgaste

La mesa se puede girar libremente 0-90 °

Fácil de manejar y ajustar rápidamente

Soporte de rodillo de soldadura

Gran capacidad portante, elevación de la pieza

Soldadura auxiliar

产品解析

Análisis de productos

| Número de serie | name | Número de serie | nombre |

| 1 | Posicionador de soldadura | 8 | Cruz soldada |

| 2 | Mandril de soldadura | 9 | Mando a distancia inalámbrico |

| 3 | Dispositivo de alimentación de alambre | 10 | Caja de control PLC |

| 4 | Oscilador de soldadura | 11 | Máquina de soldadura por arco de argón |

| 5 | El arco de argón aumenta automáticamente | 12 | Depósito de agua de refrigeración |

| 6 | Alimentador de hilo para soldadura por arco de argón | 13 | Soporte de rodillo |

| 7 | Antorcha de soldadura de arco de argón refrigerada por agua | 14 | Base eléctrica integral |

现场实拍

Tomas en directo