Horizontal Automatic Welding Machines | Tank Fabrication

- Home

- Horizontal Automatic Welding Machines | Tank Fabrication

Products

Get a Quote

Need more help?

The company always adheres to the spirit of honesty and trustworthiness.

+8618678896622

zhangrui018@gmail.com

Horizontal Automatic Welding Machines | Tank Fabrication

Horizontal double gun automatic welding machine argon arc welding two protection welding automatic welding ring welding pneumatic equipment

卧式自动焊

Horizontal autoatic welding

- Precision Motion Control: The frame is equipped with a high – precision motion control system that can accurately control the movement of the welding equipment in the horizontal direction. This ensures that the welding torch follows the desired welding path with high accuracy, resulting in excellent welding quality.

- Powerful Drive System: A powerful drive system provides the necessary force to move the welding equipment smoothly and quickly. The system offers variable speed control, allowing for different welding speeds to be adjusted according to the specific welding process and material requirements.

- Safety Protection: The frame is equipped with a comprehensive safety protection system, including emergency stop buttons, safety guards, and overload protection. These features ensure the safety of the operators and the equipment during the welding process.

The bed is welded by rectangular tube, and the appearance is painted. The transmission part is stepper motor gear drive, durable; The moving device is a guide rail and a slider, with smooth movement and high precision. It is equipped with a swinging mechanism, two-dimensional movable joints, and can adjust the Angle of the welding torch. It is suitable for automatic welding of ring seam C02, and 2 sets of welding torch devices can be configured.

Standard configuration: main engine, base, lifting bracket, pneumatic tail top, sliding beam, pneumatic lower gun, Autec welding machine welding wigger, PLC touch screen control box/hand control box, foot switch, etc.

The whole machine free warranty for one year, free installation and debugging, welding process guidance, personnel training.

Support customization.

| Model number | Horizontal autoatic welding |

| load | 300KG |

| Rotational speed | 0.5-5r/M |

| Carriage travel | 200mm |

| Column height | 1000mm |

| Clamping diameter | 20-500mm |

| Equipment weight | 680KG |

| Welding torch up and down travel | 100mm |

| Pneumatic tail top stroke | 150mm |

| Input voltage | AC22V 50HZ |

| Rotating machine | 86 stepper motor |

产品细节

Product details

PLC control box

Optional vertical control cabinet

Intelligent numerical control, stable operation

Through hole positioner

It can hold workpiece with different diameter range

Clamping is stable and accurate

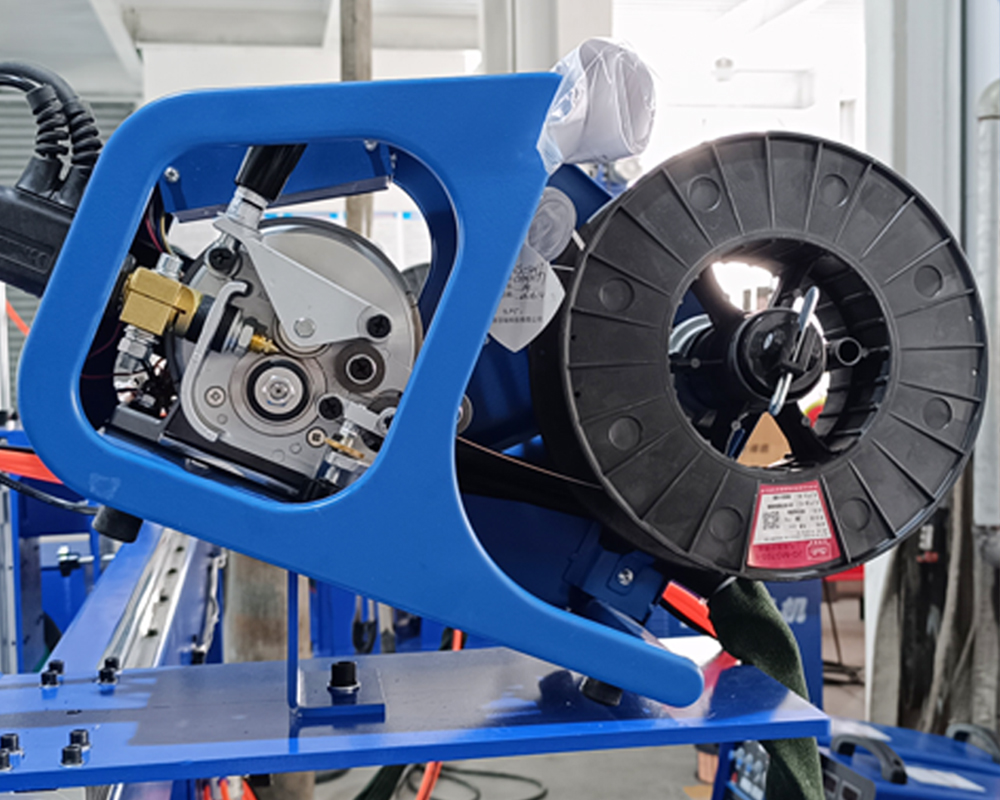

86 step wire feeder

Automatic wire feed

Easy welding

Welding chuck

Self-centering thin

Concentric rotation

Quick tightening

Large hole

产品解析

Product analysis

现场实拍

Live shooting