ZDH-1*1*2 Auto Argon/TIG Welder with Operator

- Home

- ZDH-1*1*2 Auto Argon/TIG Welder with Operator

Products

Get a Quote

Need more help?

The company always adheres to the spirit of honesty and trustworthiness.

+8618678896622

zhangrui018@gmail.com

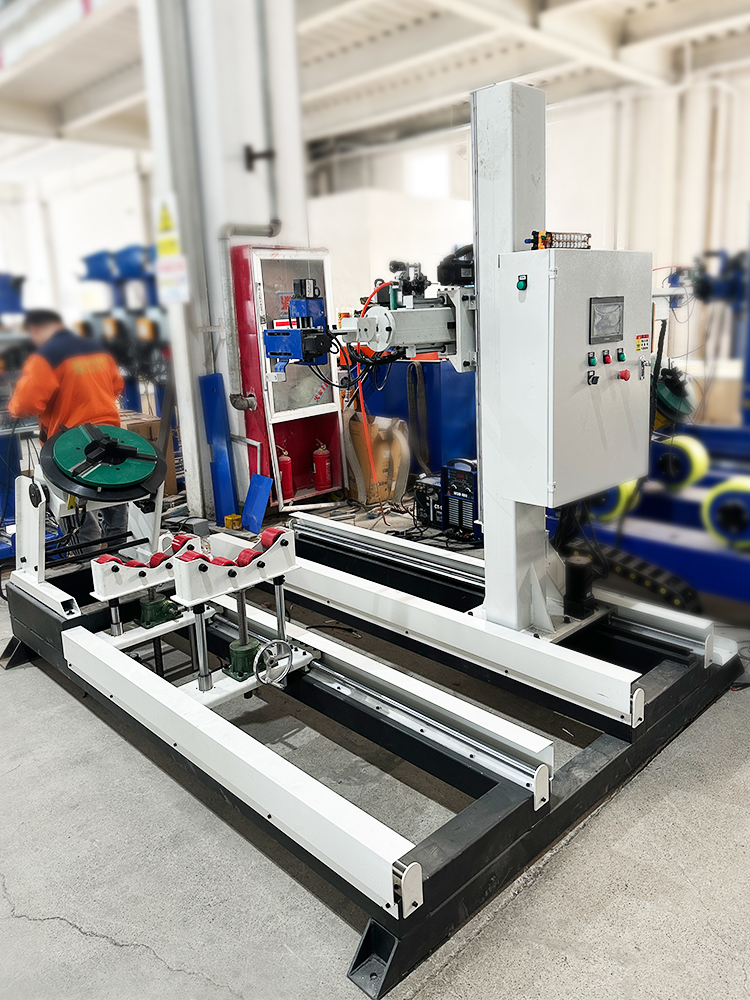

ZDH-1*1*2 Auto Argon/TIG Welder with Operator

ZDH-1*1*2 Automatic Argon Arc Welding Machine with Operator – High Precision TIG Welding Equipment for Efficient Fabrication.

氩弧自动焊1*1*2

TIG autoatic welding

Automatic Argon Arc Welding Machine with Manipulator

The automatic argon arc welding machine with manipulator is an advanced welding equipment that combines the advantages of automatic argon arc welding technology and the flexibility of a manipulator.

Working Principle

The argon arc welding part works by using a tungsten electrode to generate an arc between the electrode and the workpiece in an argon – protected environment. The heat of the arc melts the base metal and the filler wire (if used), forming a weld pool. The manipulator, on the other hand, is programmed to control the movement of the welding torch with high precision. It can follow pre – set paths, adjust the welding speed, and maintain the appropriate distance between the torch and the workpiece. This ensures consistent and high – quality welds throughout the welding process.

The walking cross type argon arc automatic welding produced by our company can be installed with C02 welding machine to achieve dual-use.

The structure is divided into three parts: the welding gun part of the welding operator, the positioner part that drives the rotation of the workpiece and the overall electric control.

Can weld stainless steel/carbon steel flange Angle welding, pipe butt weld, ring seam and straight seam of cylinder.

Standard Otai-Matsushita argon arc welding machine, including welding linkage, argon arc automatic height adjustment, CNC wire feed machine, track type positioner, bracket, starting thimble, walking machine, wireless remote control, PLC floor control cabinet, etc

The whole machine warranty for one year, free door-to-door installation and commissioning, training personnel.

Support customization.

| Model number | ZDH-1*1*2 | ||

| Positioner parameters | Manipulator parameter | ||

| Horizontal load | 600KG | Up and down stroke | 1000mm |

| Clamping diameter | 30-650mm | Anteroposterior stroke | 1000mm |

| Turnover Angle | 0-90° | Left and right straight travel | 2000mm |

| Tailstock travel | 150/2000mm | Swing arc pressure stroke | 80/80mm |

产品细节

Product details

PLC control cabinet

Intelligent numerical control, touch screen operation

Simple operation

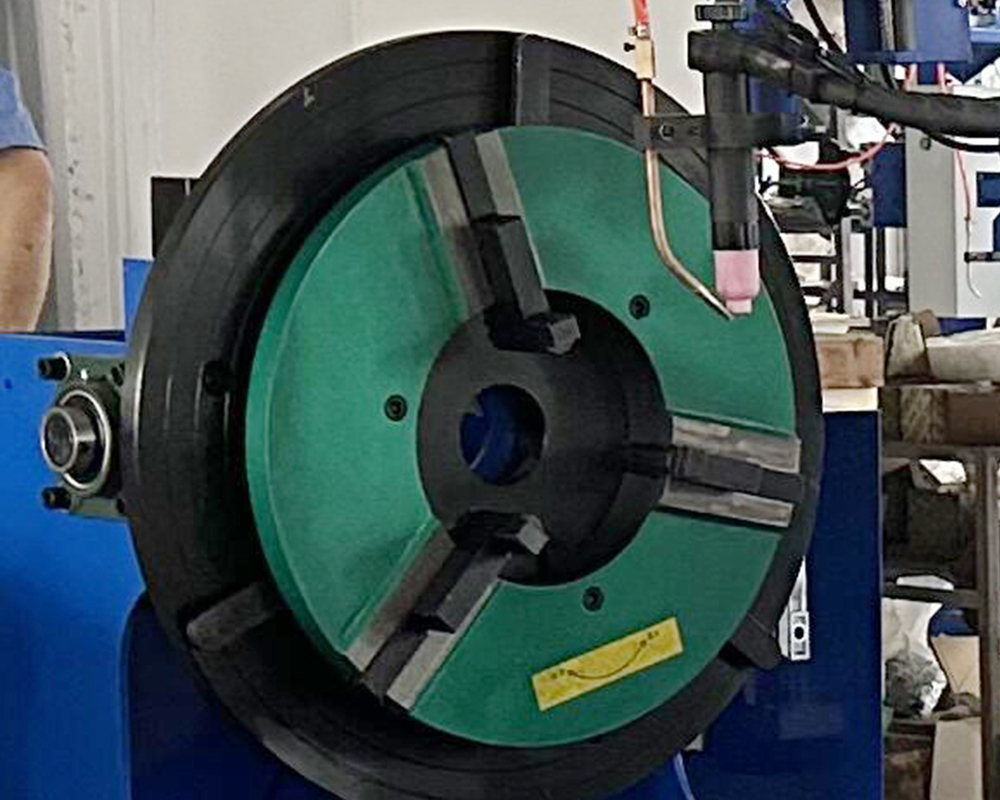

Through hole positioner

It can hold workpiece with different diameter range

Clamping is stable and accurate

Welding roller bracket

High bearing capacity, lifting workpiece

Auxiliary welding

Welding chuck

Self-centering thin,Concentric rotation

Quick tightening,Large hole

Wireless remote control

Remote control, automatic welding

Simple operation

产品解析

Product analysis

| 1 | Wireless handheld case | 7 | Wire feeding fixture | 13 | Argon arc welding machine |

| 2 | Control cabinet | 8 | Argon arc water cooled welding torch | 14 | Cooling water tank |

| 3 | Welding positioner | 9 | Angle adjustment of welding torch | 15 | Travelling motor |

| 4 | chuck | 10 | Upper and lower columns | 16 | Walking base |

| 5 | Welding oscillator | 11 | CNC wire feeder | 17 | Positioner base |

| 6 | Argon arc automatically heightens | 12 | Fore and aft beam | 18 | Slide height-adjusting bracket |

现场实拍

Live shooting